Research

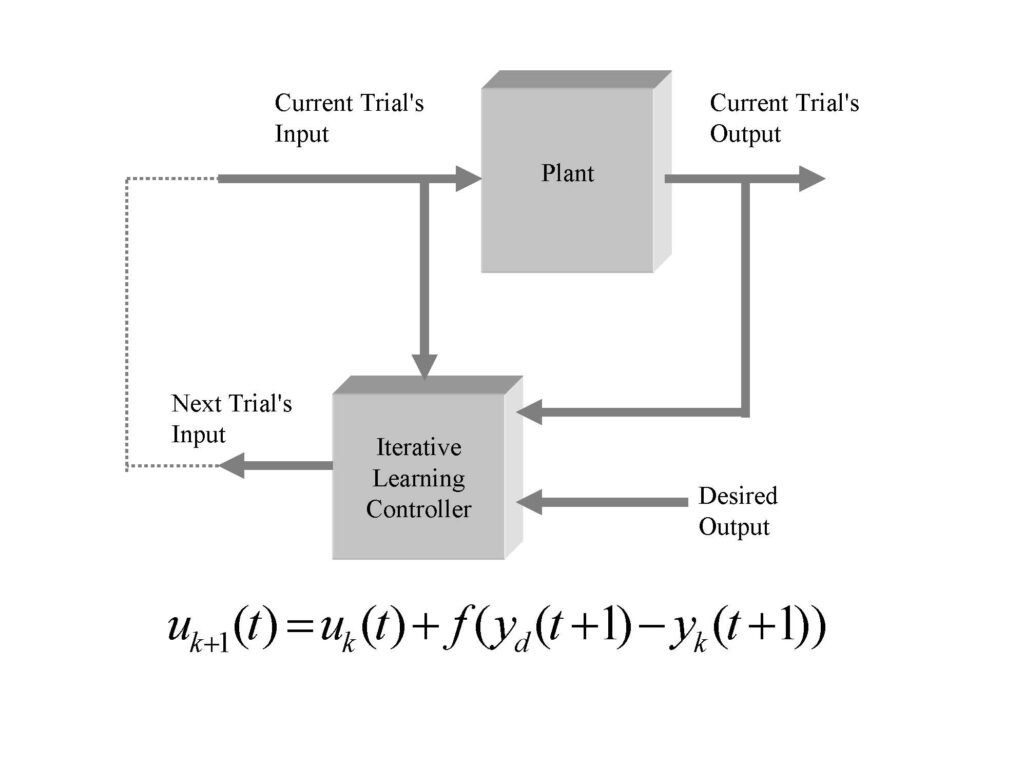

Iterative Learning Control

Iterative learning control, or ILC, is a technique used in systems that repeat the same operation over and over. It is related to repetitive control, periodic control, and discrete-repetitive processes such as multi-pass control. ILC research focuses on the design of the learning function (shown as f(.) in the figure above) and the resulting convergence and performance issues. A key point about ILC algorithms is that when each repetition starts at (or nearly at) the same initial condition, it becomes possible to implement what is effectively non-causal error filtering, because the controller implements what can be thought of as an integrator in the trial domain. More recently I have worked on the problem of discrete-repetitive processes. In these systems the plant itself has trial-to-trial memory.

.

My research in ILC began during my doctoral research in 1986. Items of interest include:

- ILC Monograph I wrote in 1993: Iterative Learning Control for Deterministic Systems, Kevin L. Moore, Springer-Verlag Series on Advances in Industrial Control, Springer-Verlag, London, January 1993.

- YangQuan Chen’s ILC page.

- Survey paper I wrote: “Iterative Learning Control: An Expository Overview,” in Applied and Computational Controls, Signal Processing, and Circuits, vol. 1, no. 1, 1998.

Some presentations:

- Introduction to ILC, March 2003. This is essentially the introductory presentation at the ILC Tutorial Workshop I organized for the 2000 CDC in Sydney.

- Montone ILC, March 2003. This was a major topic in my research from about 1998 to 2003

- Introduction to ILC, March 2006 (focuses more on the supervector approach and a unified framework for ILC).

- Robust ILC, March 2006 – this was work together with mine and YangQuan’s PhD student, Hyosung Ahn) and produced another Springer monograph (shown at left)

Autonomous Systems and Robotics

Through my early research in iterative learning control, I began to look at other forms of intelligent control, including work on architectures. When I began leading the program at USU, I then begin to focus on architectures and control algorithms to enable autonomy. My primary arena has been unmanned ground vehicles, but the ideas can also be applied to unmanned air vehicles (see the section on cooperative control below) and other robotic system applications, including for military, mining, welding, bio-medical, etc.

Some links related to this work are:

Above are some members of the CSOIS team and 6 of the 8 robots that were designed and built between 1998 and 2004, beginning under the leadership of founding director Robert Gunderson and continuing while I was center director. To the left you can see the other two robots. Most of this work was funded by the (at the time) US Army Tank-Automotive Command (TACOM), including the four ODIS robots used for under-vehicle inspection. ODIS was successfully deployed in Iraq and Afghanistan and was commercialized and for a time manufactured by Kuchera Defense Systems. In addition to these robots, CSOIS developed some autonomous tractors for precision agriculture applications (not shown). The students and staff doing that work started the still-active company Autonomous Solutions, Inc.

Mobile Sensor-Actuator Networks and Cooperative Control

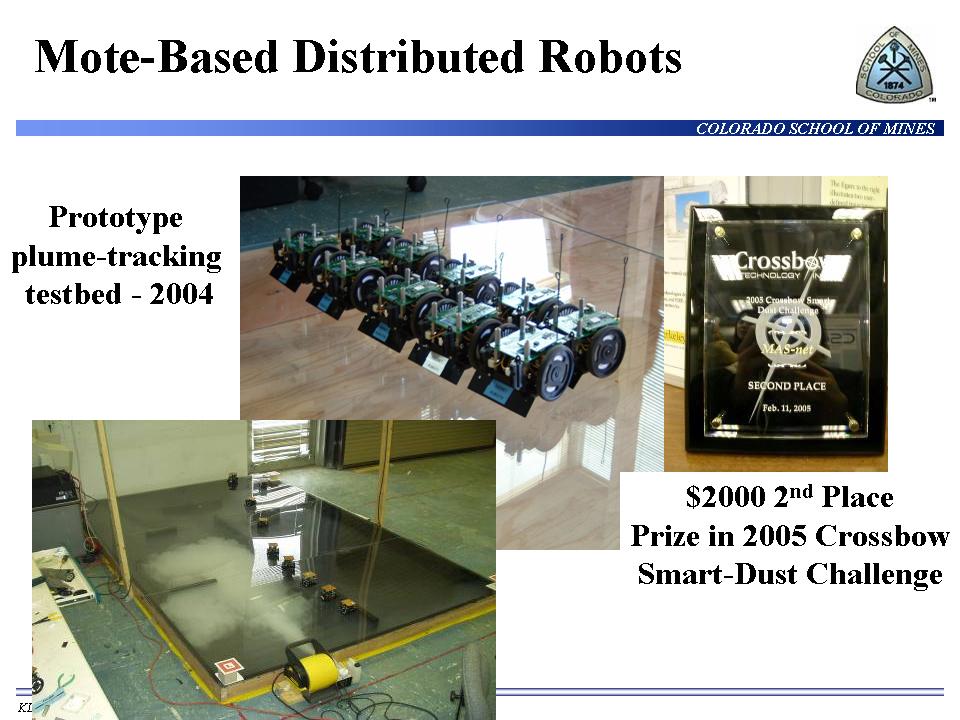

The slide above shows the 2-D aerosol testbed built at USU to test the plume tracking ideas, and the 10 mote-based robots that were used. This setup won a prize from Crossbow in 2005.

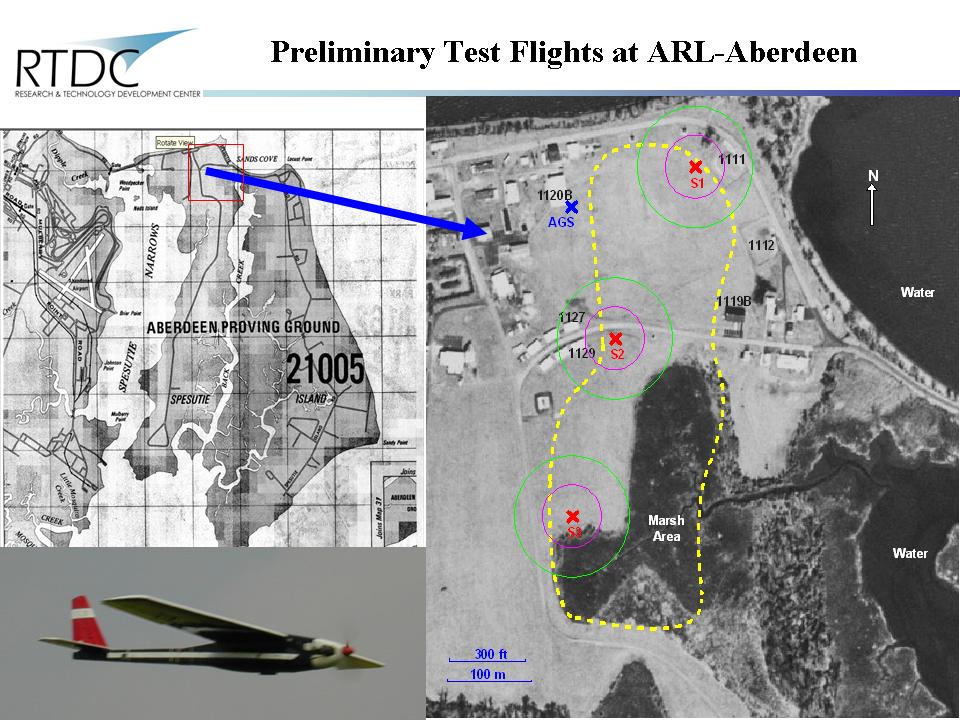

This slide shows the UAV we used at APL and a sample of a route flown using autonomous waypoint tracking for determining the connectivity map associated with a set of ground sensors.

Just before I left USU I started a project aimed at using a group of robots to sense and characterize a plume. That project, which has continued to be developed by YangQuan Chen at USU, who coined the term “MAS-Net,” which stands for “Mobile Actuator-Sensor Network,” is a subset of a broader class of problems, which I began to explore while at APL. These problems are concerned with the coordination and control of multi-agent systems, especially when the phenomena of interest are distributed and the system’s sensors and actuators are possibly mobile. I call this a dynamic resource network (DSN).

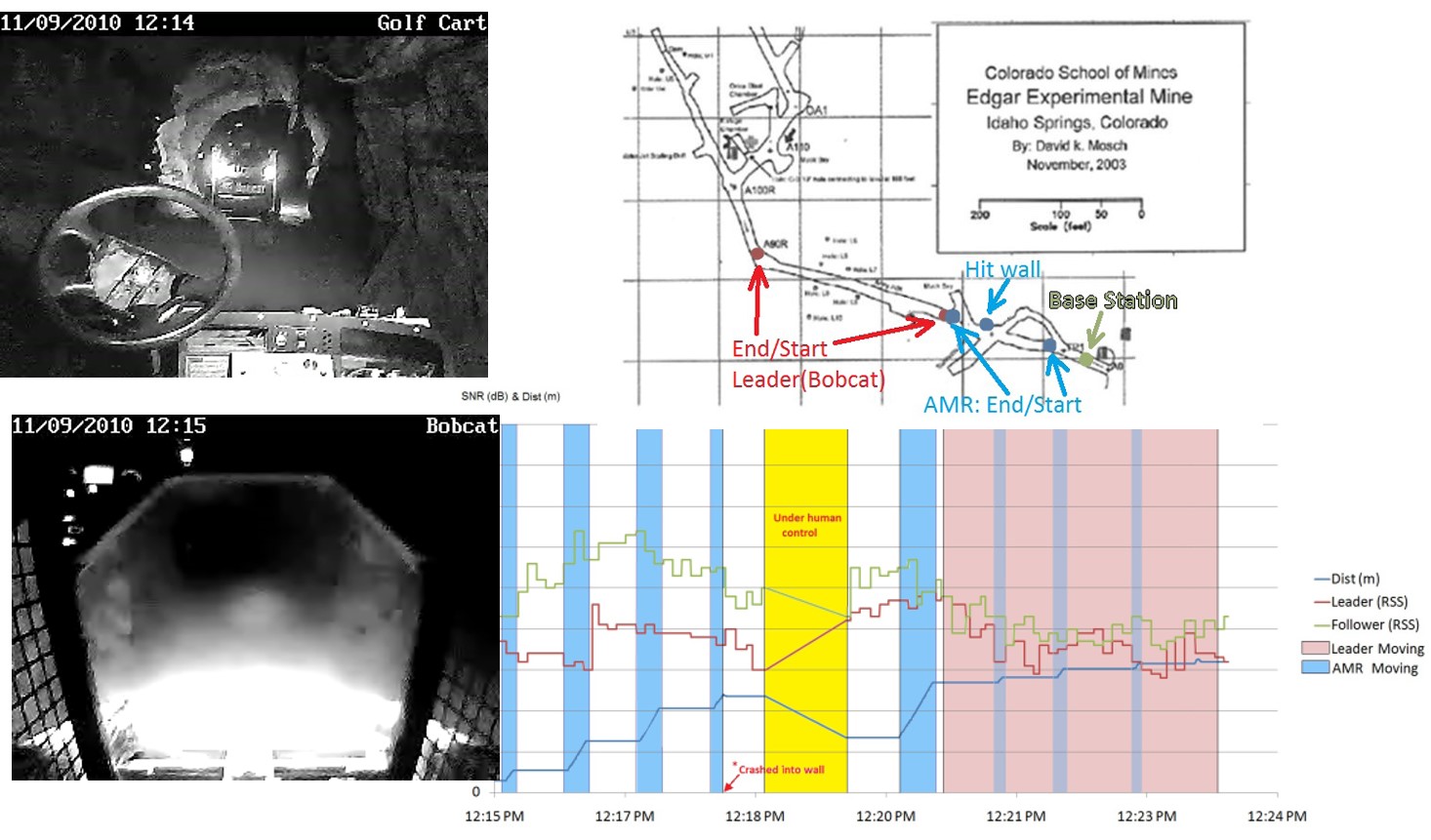

Some of my current activities have focused on developing a system-theoretic approach to cooperative resource assignment in DSNs, using a consensus variable formulation and a model-based perspective. I am also working with colleagues to apply these ideas to a diverse set of problems, from swarm UAVs, to hazardous plume tracking, to center-pivot irrigation control, to networks using robotic sensors (ground/air), to landslide prediction, to radio systems communications integrity, to underground mine safety (shown below) and more.

Some more information can be found by following these links:

- Complete summary of my ideas on this topic.

- Description of the data exfiltration project at APL, using cooperative UAVs.

- Application to adaptive scheduling for command and control.

- Conference presentation about plume tracking ideas.

- Original presentation on these ideas (March 03).

- Presentation on the MineSentry Project, applying consensus to autonomous mining safety operations

Control for Material Processing

When I was teaching at Idaho State I got involved in several projects related to controlling material processing. There were three main areas that I did research in:

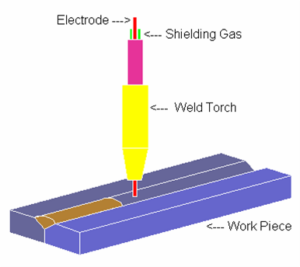

- Welding Automation – The long-term goal of this research is to achieve a “good” weld by controlling torch travel speed, electrode wire speed, torch height, and power supply properties. Our project demonstrated the ability to simultaneously control the current and arc voltage using multivariable control techniques. This research led to a book: Modeling, Sensing, and Control of Gas Metal Arc Welding, D.Subbaram Naidu, Selahattin Oozcelik, and Kevin L. Moore, Elsevier, Oxford, 2003.

- Control of the Cupola Iron-Melting Process – The project goal was to develop intelligent control of meltrate, temperature, and carbon composition, thus developing less reliance on operator experience. Three documents describing this research are:

- Aluminum Reduction (Pot Cell Control) – This was work done as a consultant, but one paper did result: TMS Paper

Above: The gas-metal arc welding process. Below: A cupola furnace is an essential part of most cast iron foundries. It is charged with coke, metal, and other materials from the top. Hot air blast with oxygen is added near the bottom. Molten iron runs out through one spout and slag through another. The cupola above was built at a DOE facility in Albany, Oregon as part of our project. It could melt about a ton an hour. Industrial cupolas may have diameters from 2’ to 15’ and melt rates from 1 to 200 tons per hour.