Fly Ash Interference with Air Entrainment

Background

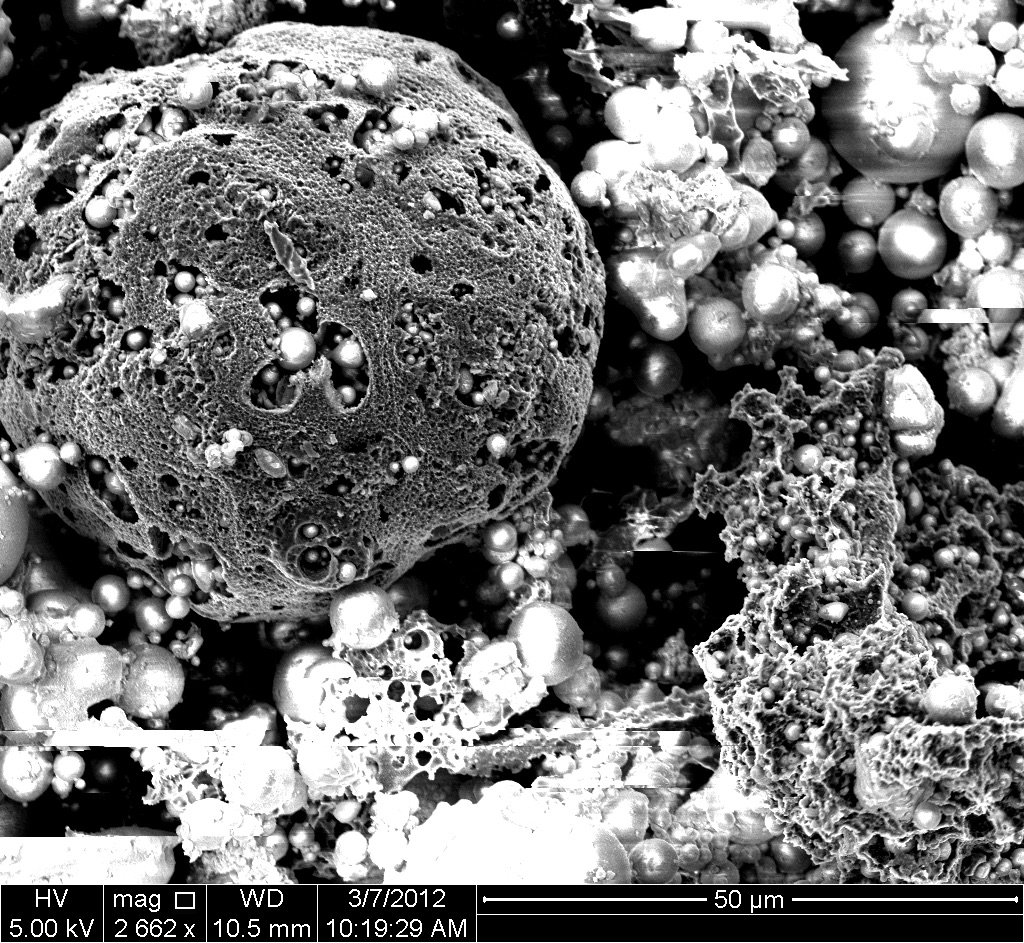

Fly ash is a byproduct of coal combustion. Depending upon the lime content in the ash, the ash can be used in concrete as either a supplementary cementitious material (class C fly ash, higher lime content) or as a pozzolanic additive (class F fly ash, lower lime content). Our research has focused on class F fly ash, which enhances many properties of concrete through a pozzolanic reaction. As the glassy silica-rich fly ash particles (bright spheres in micrograph) dissolve in the high pH solution, the silica reacts with portlandite from the cement hydration reaction to create more C-S-H (calcium silicate hydrate). Since C-S-H is what gives cement its engineering properties, such as strength and binding, fly ash can actually increase the strength of the mix. The spherical particles also act as a lubricant, improving the rheology of the mixture. While several properties are enhanced through the use of fly ash, it is a waste product which varies considerably based on coal source, processing, etc. Moreover, the carbon in fly ash (dark, porous bodies in micrograph) has been shown to interfere with air entrainment in unpredictable ways, which makes it susceptible to frost damage. This has largely been attributed to hydrophobic adsorption of the surfactant onto the hydrophobic carbon, reducing the efficacy of the air-entraining agents to support air void formation.

Summary of Results and Current Work

We found that hydrophobic adsorption of surfactant onto carbon is the dominant adsorption mechanism in DI water, but in cement pore solution chemisorption of surfactants onto the fly ash particles and/or cement prevails. We also found that 10-20 wt% of the fly ash surface area is trapped inside the larger carbon particles, which accounts for over 95% of the tiniest fly ash particles. Since other studies have shown that surfactants help with air void formation primarily by making cement particles hydrophobic, which then help in air development and stabilization of the air bubbles, our work suggests a new theory for the interference of carbon in fly ash with air entrainment: the carbon prevents fly ash particles (made hydrophobic via surfactant adsorption) from participating in air development and air void stability by limiting their mobility. Currently, we are working to develop more evidence for this theory and looking at ways to predictably compensate for air loss in the system, given the new theory. We are also developing a model to explain the strain behavior of fly ash/cement mortars and to understand how the behavior of these mortars differs from ordinary Portland cement mortars, independent of the quality of the air void system.

Relevant publications

“A New Hypothesis for Air Loss in Cement Systems Containing Fly Ash”, L.E. Tunstall, G.W. Scherer, and R.K. Prud’homme, Cement and Concrete Research 142 (April 2021): 106352

“Foam index measurements on mixes of air entraining agents, super plasticizers and fly ash-cement-filler blends”, Stefan Jacobsen, Henrik Nordahl-Pedersen, Hawar Omer Rasol, Øyvind O. Lødemel, Lori Tunstall and George W. Scherer, International RILEM conference on materials, systems and structures in civil engineering. Conference segment on frost action in concrete (August 2016)

“Influence of fly ash on air entrainment”, L.E. Tunstall and G.W. Scherer, 8 p., paper C3-1 in Proc. Int. Cong. Durability of Concrete, Trondheim, Norway, June 18-21, 2012, Eds. Harald Justnes, Stefan Jacobsen, ISBN 978-82-8208-031-6

“Predicting AEA dosage by Foam Index and adsorption on Fly Ash”, S. Jacobsen, M. Ollendorff, M. Geiker, L. Tunstall, and G.W. Scherer, pp. 103-120, Proc. Nordic Concrete Federation Workshop on Durability aspects of fly ash and slag in concrete, (Norw. Public Roads Adm. Oslo, 15-16 February 2012)